The Structures – The Problems

Xypex products play a key role in the waterproofing and protection of concrete against water penetration and aggressive chemical attack – problems typically associated with the reduced service life of concrete dam and irrigation structures.

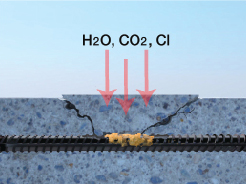

Water Permeability & Corrosion

The primary purpose of waterproofing concrete dam and irrigation structures is to prevent the intrusion of water into the structure thus protecting the reinforcing steel from the damaging effects of corrosion. The nature of concrete and the problems associated with placement and consolidation means having to deal with permeability issues permitting the penetration of water into the substrate and through to the reinforcing steel. With the presence of oxygen this can initiate corrosion.

Chemical Attack

Dam and irrigation structures are subject to attack from a variety of chemicals whether they be acidic or alkaline, organic or inorganic, man-made or natural. Sulfates may be present in water from upstream soils or mining activity. They react with calcium hydroxide in the concrete to produce an expansive reaction causing spalling and deterioration.

Abrasion

Abrasion occurs in concrete dams, irrigation channels and canals when solids moved along the channel by the flow of water gradually wear away the surface of the concrete. Eventually the reinforcing steel is exposed and corrosion initiates.

Alkali Aggregate Reaction (AAR)

Dams and irrigation structures are often constructed in remote areas offering a limited choice of aggregates for the concrete mix. Some aggregates react with the alkali hydroxides in concrete, causing expansion and cracking over a period of many years, affecting the structural integrity of the concrete.

Cracking

Cracks in concrete are the most obvious means by which water and damaging chemicals can enter a structure. These cracks are formed in a number of different ways but the most common are drying shrinkage, thermal cracking, strain formed cracks, settlement cracks and plastic shrinkage cracking.